Cadmium Telluride Solar Panel Manufacturers

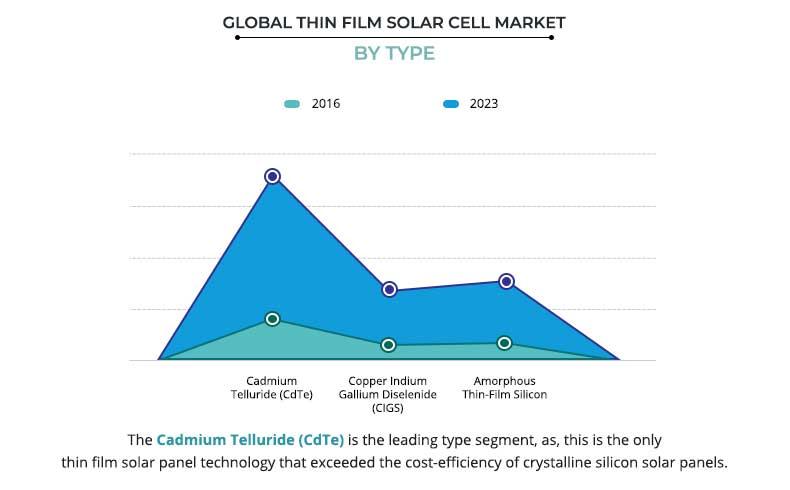

Cadmium telluride cdte is the most common type of thin film solar cell in production.

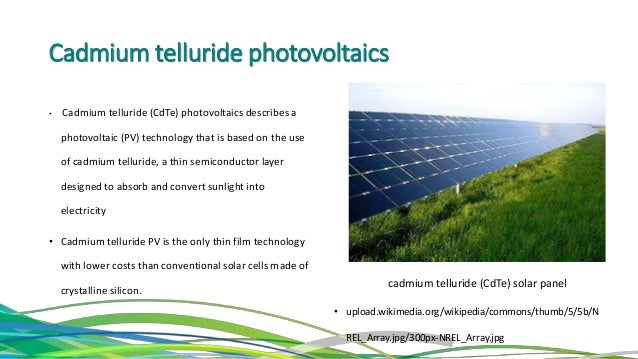

Cadmium telluride solar panel manufacturers. Company name region no. 23 cdte panel manufacturers are listed below. Cadmium telluride pv is the only thin film technology with lower costs than conventional solar cells made of crystalline silicon in multi kilowatt systems. Cadmium telluride solar cells use low cost manufacturing technology to produce low cost cells.

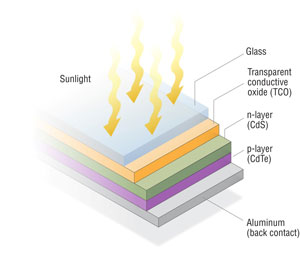

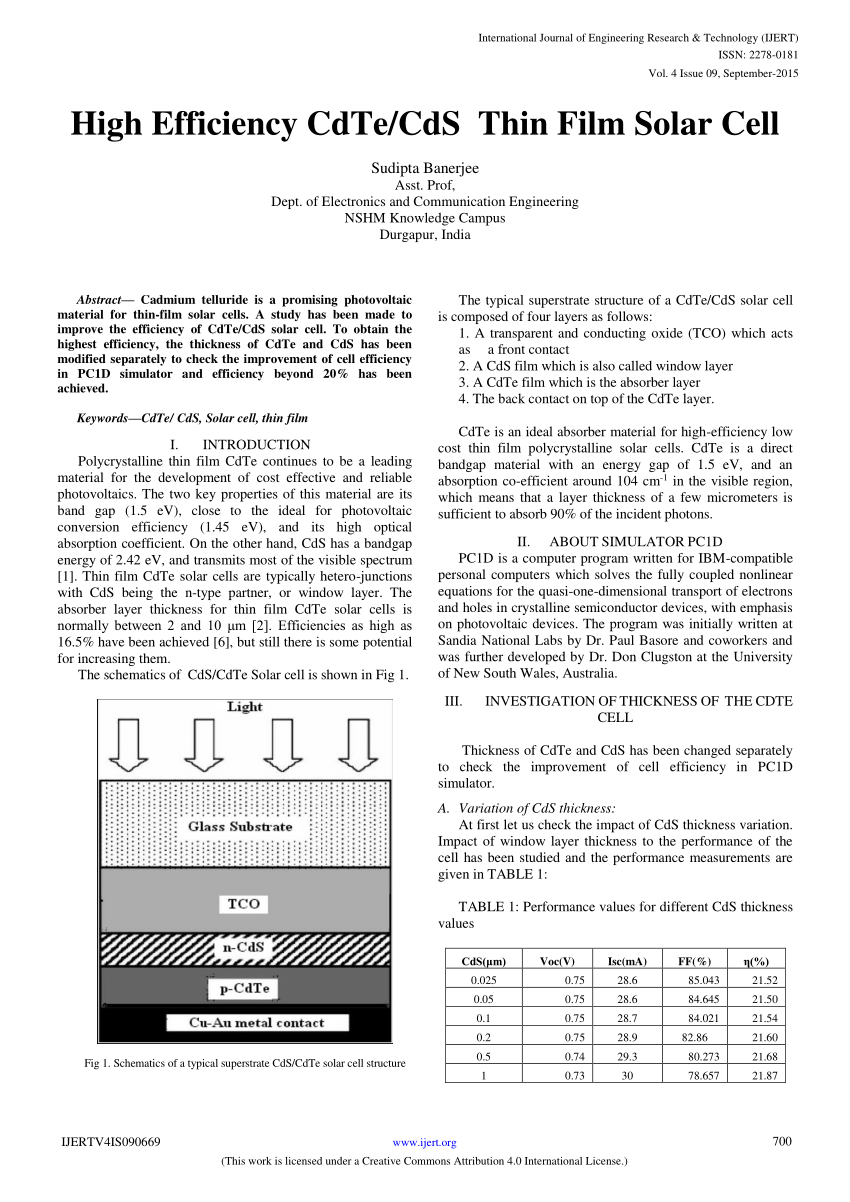

Companies involved in cdte solar panel production a key thin film panel technology. An issue with using thin film panels with a cdte is that they contain a large amount of cadmium which is a toxic element. Cadmium telluride cdte photovoltaics describes a photovoltaic pv technology that is based on the use of cadmium telluride in a thin semiconductor layer designed to absorb and convert sunlight into electricity. One main energy producing layer made from the compound cadmium telluride and surrounding layers for electricity conduction and collection.

Cdte thin film panels are made from several thin layers. The most common cdte solar cells consist of a simple p n heterojunction structure containing a p doped cdte layer matched with an n doped cadmium sulfide cds layer which acts as a window layer. First solar is an american company that works in the cadmium telluride solar panel manufacturing space. New cadmium telluride solar panels are now available for applications on tall buildings in urban environments.

Their efficiency ranges from 15 3 to 18 2 with 110 w to 450 w of power output. Advancements in solar technology and the rapidly expanding landscape of photovoltaic arrays are raising concerns about environmental toxicity namely the use of cadmium telluride cdte in most photovoltaic pv solar cells. Of known sellers power range wp advanced solar power. American manufacturing of thin film cadmium telluride cdte solar panels has been the sole domain of first solar for the last decade but now an ohio based competitor has joined the fray.

This type of substrate is the most used with manufacturing thin film solar panels and holds 50 percent of market share.