Calculating A Rolling Offset In Sheet Metal

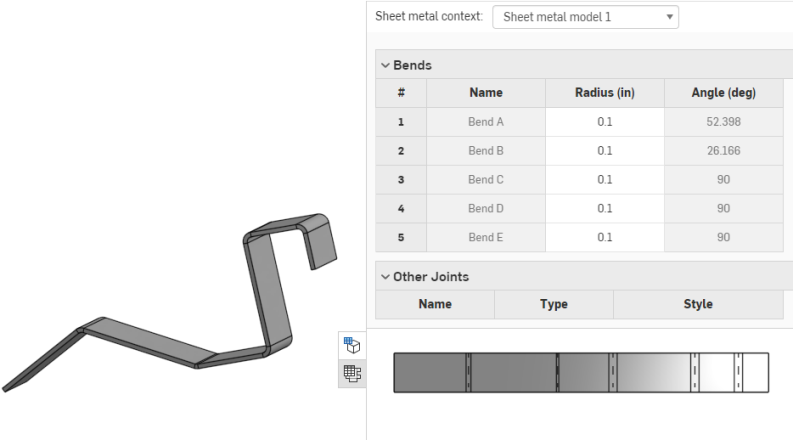

X squareroot square of v square of h travel t x cos 90 fitting angle run r squareroot square of travel t square of x.

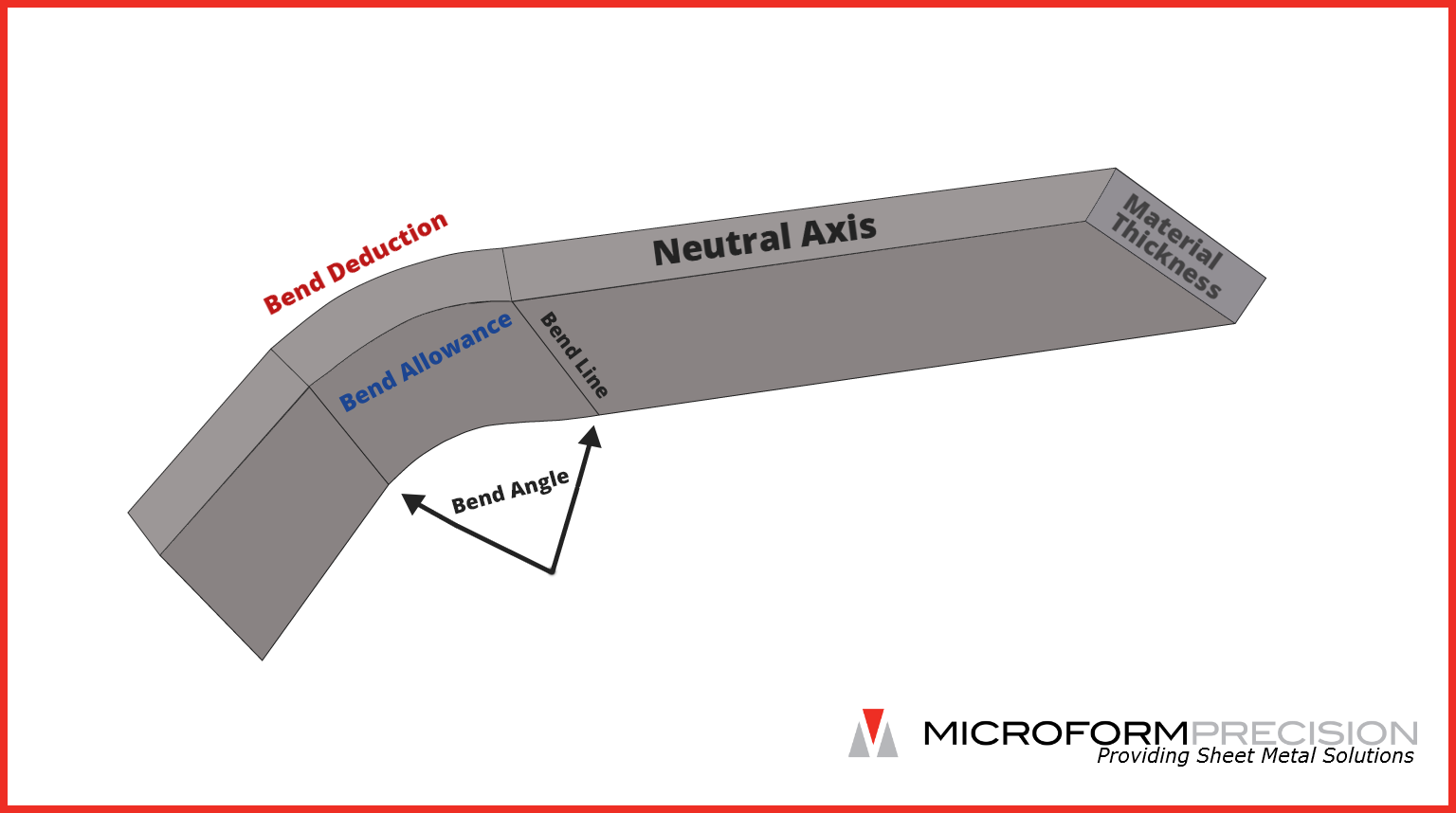

Calculating a rolling offset in sheet metal. Air bend force chart a chart used to calculate the tonnage required for a bend based on thickness tooling and length. Step 2 finding the setback and diagonal. Calculate the square root of the number to find the rolling offset. 0 059 0 097 in.

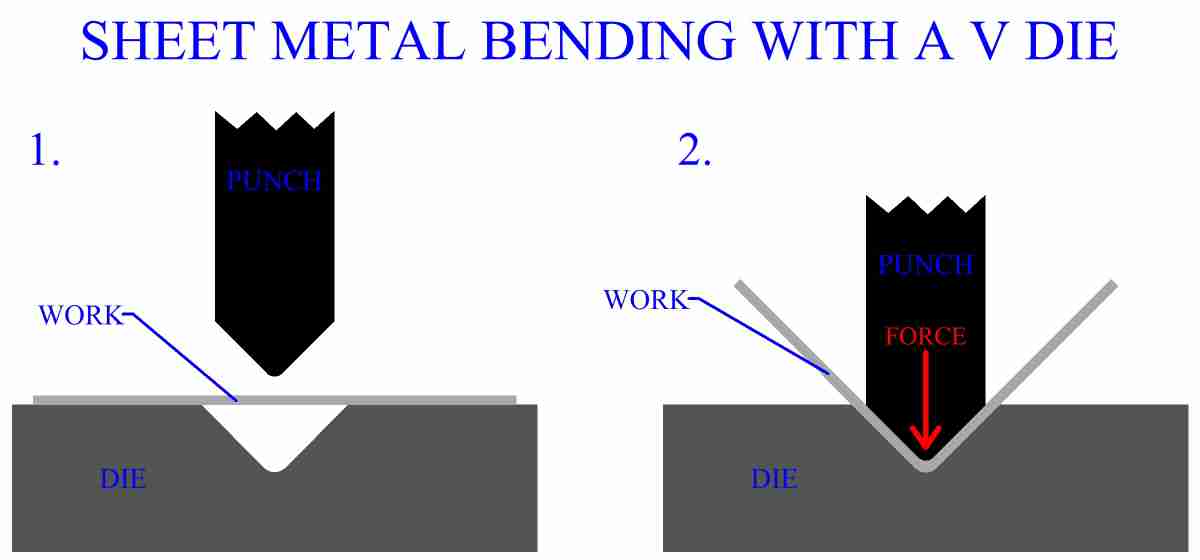

Air bending one of the three types of bending for sheet metal where the outside mold line is not pressed against the die. This page also includes a link to a on line sheet metal bend allowance calculator. In the example the square root of 208 14 42 inches. This simply means that the offset squared plus the rise squared will equal the true offset squared.

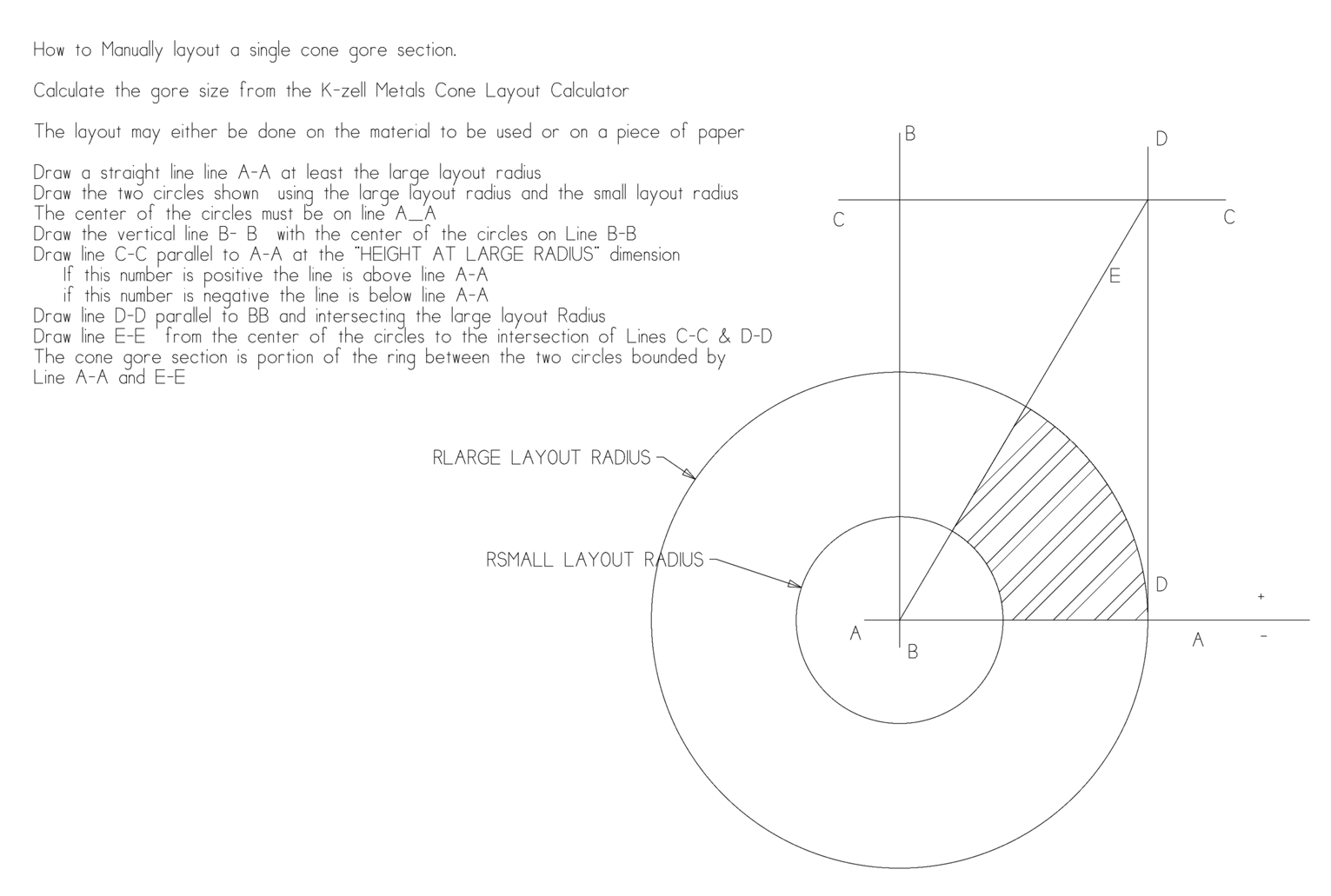

You need to calculate the circumference of the mean diameter of the ring you are rolling. The first number you need to find when calculating a rolling offset is the true offset which is found using pythagoras theorem. Punch edge radius in. You then need to take the square root of the result to get the true offset.

Windseaker1 sorry for being late getting back yes the bend formula works for rolling as well when you roll a plate you are bending it on a large radius the metal still has to shrink on the inside of the neutral line and stretch on the outside to get a finished diameter that you want you have to compensate by adding or subtracting part of the metal thickness from the neutral line. The resulting number is the offset depth as measured from the material surface. In the diagram above the relationship between the travel length and the offsets is as follows. This is used to calculate the back stop location when working off of a flat pattern.

Here you would subtract the material thickness from the specified offset. Die edge radius in. Most sheet metal materials will conform to the calculations. Say you need to form an offset specified as 0 156 inch in 0 059 in thick material.

If you are rolling a ring with a 12 inch od out of 25 inch thick material the mean diameter of the ring will be 11 75 inches. Sheet metal calculator bend allowance equations and calculator.